Please choose online customer service:

Title: The Latest Manufacturing Processes in Storage Card Production

1. Materials Used in Storage Card Manufacturing (200 words) The choice of materials plays a crucial role in the performance and durability of storage cards. Traditionally, storage cards were primarily made using plastic substrates. However, recent advancements have introduced new materials such as ceramic and metal alloys. Ceramic materials offer enhanced thermal stability and durability, making them ideal for high-performance storage cards. Metal alloys, on the other hand, provide improved electrical conductivity and resistance to electromagnetic interference.

2. Design Innovations in Storage Card Manufacturing (300 words) Design innovations have revolutionized the storage card industry, allowing for increased storage capacity and improved data transfer speeds. One such innovation is the introduction of 3D NAND technology. Unlike traditional planar NAND, 3D NAND stacks memory cells vertically, significantly increasing storage density. This technology enables the production of storage cards with larger capacities without compromising on size or performance.

Another design innovation is the implementation of advanced error correction codes (ECC). ECC algorithms help detect and correct errors that may occur during data transfer, ensuring data integrity. These algorithms have become more sophisticated, allowing for higher levels of error correction and improved reliability.

3. Fabrication Techniques in Storage Card Manufacturing (400 words) The fabrication techniques used in storage card manufacturing have also witnessed significant advancements. One notable technique is photolithography, which involves using light to transfer a pattern onto a substrate. This process is crucial for creating the intricate circuitry and memory cells on storage cards. Over the years, photolithography has become more precise, enabling the production of storage cards with smaller feature sizes and higher storage capacities.

Another important fabrication technique is wafer bonding. This process involves bonding multiple layers of substrates together to create a single storage card. Wafer bonding techniques have evolved to ensure high bonding strength and uniformity, resulting in improved card durability and performance.

Furthermore, advancements in etching techniques have allowed for the creation of smaller and more efficient memory cells. Reactive ion etching (RIE) and deep reactive ion etching (DRIE) are commonly used to etch patterns on storage card substrates. These techniques offer precise control over the etching process, resulting in smaller memory cells and increased storage density.

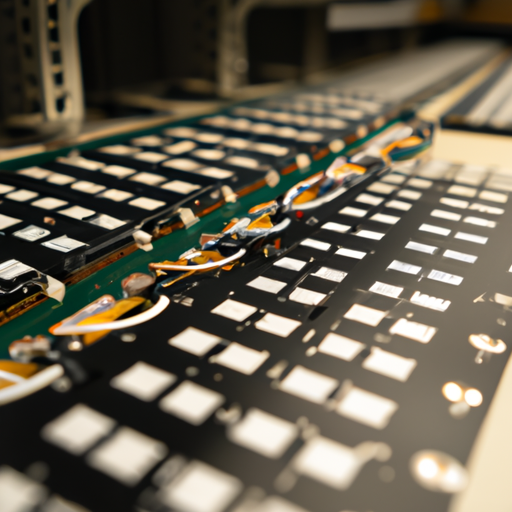

4. Assembly and Testing Processes (300 words) The assembly and testing processes are crucial stages in storage card manufacturing. Automated assembly lines have become more prevalent, ensuring efficient and accurate placement of components on the storage card. These assembly lines utilize robotic arms and computer vision systems to precisely position and solder components onto the card.

Once assembled, storage cards undergo rigorous testing to ensure their functionality and reliability. Testing processes include performance testing, data transfer speed verification, and endurance testing. Advanced testing equipment and software are employed to detect any defects or inconsistencies in the cards, ensuring only high-quality products reach the market.

Conclusion (100 words) The manufacturing processes behind storage cards have evolved significantly, driven by advancements in materials, design, and fabrication techniques. The use of new materials, such as ceramics and metal alloys, has improved the durability and performance of storage cards. Design innovations, such as 3D NAND technology and advanced ECC algorithms, have increased storage capacity and data integrity. Fabrication techniques, including photolithography and wafer bonding, have enabled the production of smaller and more efficient storage cards. The assembly and testing processes have also become more automated and rigorous, ensuring high-quality products. These advancements pave the way for even more innovative storage card solutions in the future.