Please choose online customer service:

Title: Advancements in Sensor Manufacturing Processes: Revolutionizing the World of Sensing Technology

1. Miniaturization and MEMS Technology (200 words) One of the most notable trends in sensor manufacturing is the miniaturization of sensors, enabled by Micro-Electro-Mechanical Systems (MEMS) technology. MEMS sensors are fabricated using semiconductor manufacturing techniques, allowing for the integration of mechanical and electrical components on a single chip. This miniaturization has led to the development of sensors that are smaller, more efficient, and cost-effective. MEMS sensors find applications in smartphones, wearables, and IoT devices, revolutionizing the way we interact with technology.

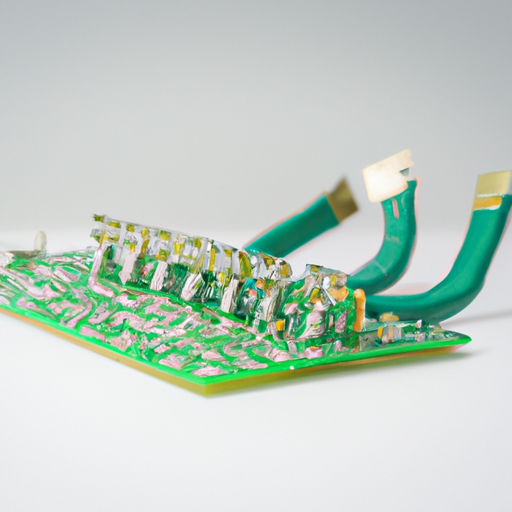

2. 3D Printing and Additive Manufacturing (200 words) The advent of 3D printing and additive manufacturing has brought significant advancements to sensor manufacturing. This technology allows for the creation of complex sensor designs with intricate geometries, enhancing their performance and functionality. 3D printing enables the production of customized sensors, reducing lead times and costs. Additionally, it facilitates the integration of multiple sensors into a single device, enabling multi-functionality and improved data accuracy.

3. Flexible and Stretchable Sensors (200 words) Flexible and stretchable sensors have gained immense popularity due to their ability to conform to irregular surfaces and withstand mechanical stress. These sensors are manufactured using flexible substrates, such as polymers or elastomers, combined with conductive materials. The manufacturing process involves printing or deposition techniques, enabling the creation of sensors that can be bent, twisted, or stretched without compromising their functionality. Applications of flexible and stretchable sensors include wearable health monitoring devices, robotics, and human-machine interfaces.

4. Nanotechnology and Nanosensors (200 words) Nanotechnology has revolutionized sensor manufacturing by enabling the development of nanosensors with exceptional sensitivity and selectivity. Nanosensors are fabricated using nanomaterials, such as carbon nanotubes, graphene, or nanoparticles, which exhibit unique properties at the nanoscale. The manufacturing process involves precise deposition techniques, such as chemical vapor deposition or atomic layer deposition, to create nanoscale structures. Nanosensors find applications in environmental monitoring, medical diagnostics, and food safety, offering enhanced detection capabilities and improved performance.

5. Smart Sensor Integration and IoT (200 words) The integration of sensors with the Internet of Things (IoT) has opened up new possibilities for sensor manufacturing. Smart sensors, equipped with wireless connectivity and data processing capabilities, enable real-time monitoring and analysis. The manufacturing process involves the integration of microcontrollers, wireless communication modules, and power management circuits into the sensor design. Smart sensors find applications in smart homes, industrial automation, and smart cities, enabling efficient data collection, analysis, and decision-making.

Conclusion (100 words) Sensor manufacturing processes have witnessed remarkable advancements, driven by the need for smaller, more efficient, and versatile sensors. Miniaturization, 3D printing, flexible and stretchable sensors, nanotechnology, and smart sensor integration are some of the latest trends in sensor manufacturing. These advancements have revolutionized various industries, from healthcare and automotive to consumer electronics and environmental monitoring. As technology continues to evolve, sensor manufacturing processes will likely continue to push the boundaries of what is possible, enabling new applications and improving the quality of life for individuals worldwide.