Please choose online customer service:

What are the Product Features of Chip Resistors?

I. Introduction

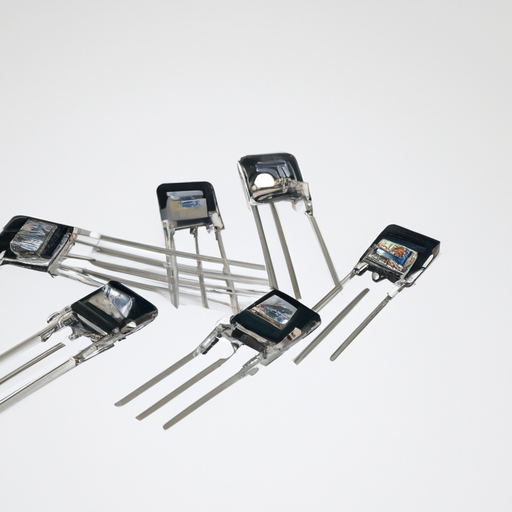

A. Definition of Chip Resistors

Chip resistors, also known as surface-mount resistors, are small electronic components used to limit the flow of electric current in a circuit. They are designed to be mounted directly onto the surface of printed circuit boards (PCBs), making them essential for modern electronic devices where space is at a premium.

B. Importance of Chip Resistors in Electronic Circuits

Chip resistors play a critical role in electronic circuits by providing precise resistance values, which are crucial for controlling current, voltage, and signal levels. Their compact size and reliability make them ideal for a wide range of applications, from consumer electronics to industrial machinery.

C. Overview of the Article

This article will explore the various types of chip resistors, their key product features, material composition, manufacturing processes, applications, and future trends in technology. By understanding these aspects, designers and engineers can make informed decisions when selecting chip resistors for their projects.

II. Types of Chip Resistors

1. Characteristics

Thin film resistors are made by depositing a thin layer of resistive material onto a substrate. They offer high precision, low noise, and excellent temperature stability.

2. Applications

These resistors are commonly used in applications requiring high accuracy, such as precision measurement devices and high-frequency circuits.

1. Characteristics

Thick film resistors are created by screen printing a thick layer of resistive paste onto a substrate. They are generally less expensive than thin film resistors and can handle higher power levels.

2. Applications

Thick film resistors are widely used in consumer electronics, automotive applications, and general-purpose circuits.

1. Characteristics

Wirewound resistors consist of a wire wound around a core. They are known for their high power ratings and excellent stability.

2. Applications

These resistors are often used in power applications, such as power supplies and motor controls.

1. Metal Film Resistors

Metal film resistors offer low noise and high stability, making them suitable for audio and precision applications.

2. Carbon Film Resistors

Carbon film resistors are cost-effective and provide good performance for general applications.

III. Key Product Features of Chip Resistors

1. Range of Values

Chip resistors are available in a wide range of resistance values, typically from a few ohms to several megaohms, allowing designers to select the appropriate value for their specific application.

2. Tolerance Levels

Tolerance indicates how much the actual resistance can vary from the specified value. Common tolerance levels for chip resistors include ±1%, ±5%, and ±10%.

1. Definition and Importance

Power rating refers to the maximum amount of power a resistor can dissipate without overheating. It is crucial for ensuring the reliability and longevity of the component.

2. Common Power Ratings

Chip resistors typically have power ratings ranging from 1/16 watt to several watts, depending on their size and construction.

1. Explanation of Temperature Coefficient

The temperature coefficient indicates how much a resistor's value changes with temperature. It is expressed in parts per million per degree Celsius (ppm/°C).

2. Impact on Performance

A low temperature coefficient is desirable for applications requiring stable performance over varying temperatures, such as precision instrumentation.

1. Standard Sizes (0402, 0603, etc.)

Chip resistors come in standardized sizes, such as 0402, 0603, and 0805, which refer to their dimensions in inches. The choice of size affects the resistor's power rating and suitability for different applications.

2. Impact on PCB Design

The size of chip resistors influences PCB layout and design, as smaller components allow for more compact designs but may require more careful handling during assembly.

1. Definition and Importance

Voltage rating indicates the maximum voltage that can be applied across a resistor without risking breakdown or failure.

2. Common Voltage Ratings

Chip resistors typically have voltage ratings ranging from 25V to 200V, with higher ratings available for specialized applications.

1. Types of Noise

Resistors can generate thermal noise, shot noise, and flicker noise, which can affect circuit performance, especially in sensitive applications.

2. Importance in Sensitive Applications

Low-noise resistors are essential in audio and RF applications, where signal integrity is critical.

1. Factors Affecting Reliability

Factors such as temperature, humidity, and mechanical stress can impact the reliability of chip resistors. Selecting components with high reliability ratings is crucial for mission-critical applications.

2. Testing Standards (e.g., MIL-PRF-55342)

Many chip resistors are tested according to industry standards, such as MIL-PRF-55342, to ensure they meet specific reliability and performance criteria.

IV. Material Composition

1. Metal Films

Metal films are commonly used in thin film resistors due to their excellent stability and low noise characteristics.

2. Carbon Films

Carbon films are often used in thick film resistors, providing a cost-effective solution for general applications.

1. Ceramic

Ceramic substrates are widely used for their thermal stability and electrical insulation properties.

2. Epoxy

Epoxy substrates are often used in low-cost applications, providing adequate performance for many consumer electronics.

1. Protective Coatings

Protective coatings are applied to resistors to enhance their durability and resistance to environmental factors.

2. Environmental Resistance

Resistors designed for harsh environments may feature coatings that provide additional protection against moisture, dust, and chemicals.

V. Manufacturing Processes

1. Deposition Techniques

Thin film resistors are manufactured using techniques such as sputtering and evaporation, which allow for precise control over the resistive layer.

2. Advantages and Disadvantages

While thin film technology offers high precision and stability, it can be more expensive than other methods.

1. Screen Printing Process

Thick film resistors are produced using a screen printing process, which is cost-effective for mass production.

2. Advantages and Disadvantages

Thick film technology is less precise than thin film but is suitable for a wide range of applications due to its lower cost.

1. Testing Procedures

Manufacturers implement rigorous testing procedures to ensure that resistors meet specified performance criteria.

2. Certification Standards

Many chip resistors are certified to industry standards, ensuring their reliability and performance in various applications.

VI. Applications of Chip Resistors

A. Consumer Electronics

Chip resistors are widely used in smartphones, tablets, and other consumer devices, where space and performance are critical.

B. Automotive Industry

In automotive applications, chip resistors are used in control systems, sensors, and infotainment systems, requiring high reliability and performance.

C. Telecommunications

Chip resistors are essential in telecommunications equipment, where they help manage signal integrity and power levels.

D. Industrial Equipment

In industrial settings, chip resistors are used in control systems, automation, and monitoring equipment, demanding high durability and stability.

E. Medical Devices

Medical devices require precise and reliable components, making chip resistors vital in applications such as diagnostic equipment and patient monitoring systems.

VII. Future Trends in Chip Resistor Technology

A. Miniaturization

As electronic devices continue to shrink, the demand for smaller chip resistors will grow, driving innovation in manufacturing processes and materials.

B. Enhanced Performance Features

Future chip resistors may feature improved performance characteristics, such as lower noise and better temperature stability, to meet the demands of advanced applications.

C. Eco-Friendly Materials

With increasing environmental concerns, manufacturers are exploring eco-friendly materials and processes to reduce the environmental impact of chip resistor production.

D. Smart Resistors

The development of smart resistors that can provide real-time feedback and monitoring capabilities is an exciting trend that could revolutionize circuit design.

VIII. Conclusion

A. Summary of Key Features

Chip resistors are essential components in modern electronics, offering a range of features such as precise resistance values, power ratings, and reliability. Understanding these features is crucial for selecting the right resistor for specific applications.

B. Importance of Selecting the Right Chip Resistor

Choosing the appropriate chip resistor can significantly impact the performance and reliability of electronic devices. Engineers must consider factors such as resistance value, power rating, and environmental conditions when making their selection.

C. Final Thoughts on the Role of Chip Resistors in Modern Electronics

As technology continues to evolve, chip resistors will remain a fundamental component in electronic design. Their versatility and reliability make them indispensable in a wide range of applications, from consumer electronics to critical industrial systems.

IX. References

A. Academic Journals

- IEEE Transactions on Components, Packaging and Manufacturing Technology

- Journal of Electronic Materials

B. Industry Reports

- Market Research Reports on Passive Components

- Industry Analysis on Chip Resistor Trends

C. Manufacturer Specifications

- Datasheets from leading chip resistor manufacturers

- Technical documentation on chip resistor technology

This comprehensive overview of chip resistors highlights their importance, features, and applications, providing valuable insights for engineers and designers in the electronics industry.