Please choose online customer service:

Mainstream Wirewound Resistor Product Series Parameters

I. Introduction

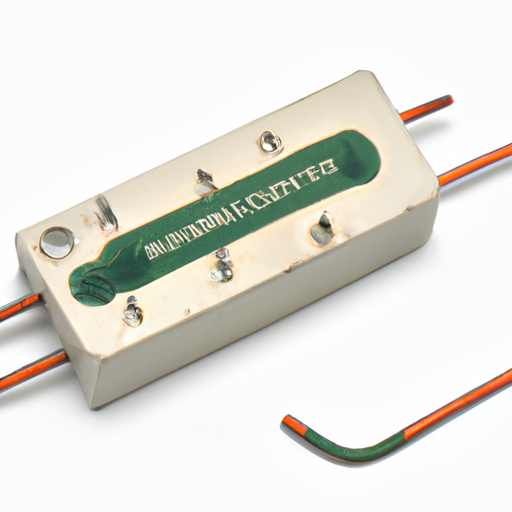

A. Definition of Wirewound Resistors

Wirewound resistors are a type of resistor that is constructed by winding a metal wire around a core. This design allows for precise resistance values and high power ratings, making them a popular choice in various electronic applications. The wire is typically made from materials such as nickel-chromium or copper-nickel, which provide excellent conductivity and thermal stability.

B. Importance of Wirewound Resistors in Electronic Circuits

Wirewound resistors play a crucial role in electronic circuits by controlling current flow, dividing voltages, and providing load resistance. Their ability to handle high power levels and maintain stability under varying conditions makes them indispensable in many applications, from industrial machinery to consumer electronics.

C. Overview of the Article's Purpose and Scope

This article aims to provide a comprehensive overview of mainstream wirewound resistor product series parameters. We will explore the different types of wirewound resistors, their key parameters, construction materials, performance characteristics, applications, and selection criteria. By the end of this article, readers will have a better understanding of wirewound resistors and their significance in electronic design.

II. Types of Wirewound Resistors

A. Standard Wirewound Resistors

1. Characteristics

Standard wirewound resistors are designed for general-purpose applications. They typically offer a wide range of resistance values and power ratings, making them versatile components in electronic circuits.

2. Applications

These resistors are commonly used in power supplies, amplifiers, and other electronic devices where standard resistance values are required.

B. Precision Wirewound Resistors

1. Characteristics

Precision wirewound resistors are designed for applications that require high accuracy and low tolerance levels. They are manufactured with tighter specifications to ensure consistent performance.

2. Applications

These resistors are often used in measurement and calibration equipment, as well as in high-precision circuits where accuracy is paramount.

C. High-Power Wirewound Resistors

1. Characteristics

High-power wirewound resistors are built to handle significant power loads. They are typically larger and constructed with materials that can dissipate heat effectively.

2. Applications

These resistors are commonly found in industrial applications, such as motor control circuits and power electronics, where high power handling is essential.

D. Specialty Wirewound Resistors

1. Characteristics

Specialty wirewound resistors are designed for specific applications or environments. They may have unique features, such as high-temperature ratings or specific resistance values.

2. Applications

These resistors are used in niche applications, including aerospace, military, and medical devices, where standard resistors may not meet the requirements.

III. Key Parameters of Wirewound Resistors

A. Resistance Value

1. Measurement Units (Ohms)

The resistance value of wirewound resistors is measured in ohms (Ω). This value determines how much current will flow through the resistor when a voltage is applied.

2. Tolerance Levels

Tolerance levels indicate how much the actual resistance can vary from the specified value. Common tolerance levels for wirewound resistors range from 0.1% to 5%, depending on the type and application.

B. Power Rating

1. Definition and Importance

The power rating of a wirewound resistor indicates the maximum amount of power it can dissipate without overheating. Exceeding this rating can lead to failure or damage.

2. Common Power Ratings in Wirewound Resistors

Wirewound resistors are available in various power ratings, typically ranging from a few watts to several hundred watts, depending on the design and application.

C. Temperature Coefficient

1. Explanation of Temperature Coefficient

The temperature coefficient measures how much the resistance value changes with temperature. It is expressed in parts per million per degree Celsius (ppm/°C).

2. Impact on Performance

A low temperature coefficient is desirable, as it indicates that the resistor will maintain its resistance value over a wide temperature range, ensuring stable performance in varying conditions.

D. Inductance

1. Definition and Relevance

Inductance refers to the tendency of a resistor to oppose changes in current due to its physical construction. It is an important parameter in high-frequency applications.

2. How Inductance Affects Circuit Performance

High inductance can lead to unwanted effects in circuits, such as signal distortion or reduced performance. Therefore, understanding inductance is crucial when selecting wirewound resistors for specific applications.

E. Voltage Rating

1. Importance of Voltage Rating

The voltage rating indicates the maximum voltage that can be applied across the resistor without causing breakdown or failure. Exceeding this rating can lead to catastrophic failure.

2. Common Voltage Ratings in Wirewound Resistors

Wirewound resistors are available with various voltage ratings, typically ranging from a few volts to several kilovolts, depending on the application requirements.

IV. Construction and Materials

A. Wire Material

1. Common Materials Used (e.g., Nickel-Chromium, Copper-Nickel)

The wire used in wirewound resistors is typically made from materials like nickel-chromium or copper-nickel, which provide excellent conductivity and thermal stability.

2. Impact on Performance and Durability

The choice of wire material affects the resistor's performance, including its resistance value, temperature coefficient, and overall durability.

B. Core Material

1. Types of Core Materials (e.g., Ceramic, Plastic)

The core material provides structural support and thermal management for the resistor. Common materials include ceramic and plastic, each offering different thermal and mechanical properties.

2. Influence on Thermal Management

The core material plays a significant role in heat dissipation, which is critical for maintaining performance and preventing damage in high-power applications.

C. Coating and Insulation

1. Types of Coatings (e.g., Epoxy, Silicone)

Wirewound resistors are often coated with materials like epoxy or silicone to provide insulation and protect against environmental factors.

2. Importance of Insulation in Performance

Proper insulation is essential for preventing short circuits and ensuring reliable performance in various operating conditions.

V. Performance Characteristics

A. Stability and Reliability

1. Factors Affecting Stability

Stability can be influenced by factors such as temperature, humidity, and mechanical stress. Understanding these factors is crucial for selecting the right resistor for specific applications.

2. Testing Methods for Reliability

Reliability testing methods, such as thermal cycling and load testing, help ensure that wirewound resistors will perform consistently over time.

B. Frequency Response

1. Importance of Frequency Response in Applications

Frequency response is critical in applications where resistors are subjected to varying frequencies, such as in audio equipment or RF circuits.

2. How Wirewound Resistors Perform at Different Frequencies

Wirewound resistors generally perform well at low frequencies but may exhibit increased inductance at higher frequencies, affecting their overall performance.

C. Noise Characteristics

1. Definition of Noise in Resistors

Noise in resistors refers to the unwanted electrical signals that can interfere with circuit performance. It is typically measured in terms of voltage noise.

2. Comparison with Other Resistor Types

Wirewound resistors tend to have lower noise levels compared to other resistor types, such as carbon film resistors, making them suitable for precision applications.

VI. Applications of Wirewound Resistors

A. Industrial Applications

1. Use in Power Supplies

Wirewound resistors are commonly used in power supplies to regulate voltage and current, ensuring stable operation of electronic devices.

2. Role in Motor Control Circuits

In motor control circuits, wirewound resistors help manage power levels and protect against overloads, contributing to the overall efficiency of the system.

B. Consumer Electronics

1. Applications in Audio Equipment

Wirewound resistors are often used in audio equipment to maintain signal integrity and minimize distortion, enhancing the overall listening experience.

2. Use in Home Appliances

In home appliances, these resistors help regulate power and ensure reliable operation, contributing to the longevity of the devices.

C. Automotive Applications

1. Importance in Automotive Electronics

Wirewound resistors are critical components in automotive electronics, where they help manage power levels and ensure the reliability of various systems.

2. Specific Use Cases

They are commonly used in applications such as engine control units, power steering systems, and braking systems, where precision and reliability are essential.

D. Medical Devices

1. Role in Medical Equipment

In medical devices, wirewound resistors are used for their precision and reliability, ensuring accurate measurements and safe operation.

2. Importance of Precision and Reliability

The high accuracy and stability of wirewound resistors make them ideal for applications in medical equipment, where even minor deviations can have significant consequences.

VII. Selection Criteria for Wirewound Resistors

A. Application Requirements

1. Understanding Specific Needs

When selecting wirewound resistors, it is essential to understand the specific requirements of the application, including resistance value, power rating, and environmental conditions.

2. Matching Resistor Types to Applications

Choosing the right type of wirewound resistor for the application is crucial for ensuring optimal performance and reliability.

B. Environmental Considerations

1. Operating Temperature Range

Consideration of the operating temperature range is vital, as it affects the resistor's performance and longevity.

2. Humidity and Other Environmental Factors

Environmental factors such as humidity and exposure to chemicals can impact the performance of wirewound resistors, making it essential to select resistors that can withstand these conditions.

C. Cost vs. Performance

1. Balancing Budget with Quality

When selecting wirewound resistors, it is important to balance cost with performance to ensure that the chosen components meet the application's requirements without exceeding the budget.

2. Long-term Value Considerations

Investing in high-quality wirewound resistors can lead to long-term savings by reducing the need for replacements and maintenance.

VIII. Conclusion

A. Summary of Key Points

Wirewound resistors are essential components in electronic circuits, offering a range of types and parameters to suit various applications. Understanding their characteristics, construction, and performance is crucial for selecting the right resistor for specific needs.

B. Future Trends in Wirewound Resistor Technology

As technology advances, wirewound resistors are likely to see improvements in materials and manufacturing processes, leading to enhanced performance and reliability.

C. Final Thoughts on the Importance of Understanding Resistor Parameters

A thorough understanding of wirewound resistor parameters is vital for engineers and designers to ensure optimal performance in their electronic applications. By considering factors such as resistance value, power rating, and environmental conditions, one can make informed decisions that lead to successful designs.

IX. References

A. Suggested Reading and Resources

1. "Resistor Technology: A Comprehensive Guide" - Electronics Journal

2. "Understanding Wirewound Resistors" - Resistor Manufacturers Association

B. Industry Standards and Guidelines

1. IEC 60115 - Resistors for Electronic Equipment

2. EIA-198 - Standard for Wirewound Resistors

This blog post provides a detailed overview of wirewound resistors, their parameters, and their applications, serving as a valuable resource for anyone looking to understand these essential components in electronic design.