Please choose online customer service:

What are the Product Features of Pulse Capacitors?

I. Introduction

A. Definition of Pulse Capacitors

Pulse capacitors are specialized capacitors designed to handle high-energy pulses and rapid charge and discharge cycles. Unlike standard capacitors, which are typically used for smoothing and filtering applications, pulse capacitors are engineered to deliver quick bursts of energy, making them essential in various high-performance applications.

B. Importance of Pulse Capacitors in Various Applications

The unique characteristics of pulse capacitors make them invaluable in fields such as power electronics, telecommunications, automotive technology, and medical devices. Their ability to manage high energy levels and rapid discharge rates allows for improved performance and efficiency in systems that require quick energy delivery.

C. Overview of the Article

This article will explore the basic principles of pulse capacitors, their key features, types, applications, advantages, and the challenges associated with their use. By understanding these aspects, readers will gain insight into the critical role pulse capacitors play in modern technology.

II. Basic Principles of Pulse Capacitors

A. How Pulse Capacitors Work

1. Charge and Discharge Mechanism

Pulse capacitors operate on the same fundamental principles as standard capacitors, storing electrical energy in an electric field. However, they are designed to handle much higher rates of charge and discharge, allowing them to release energy quickly when needed.

2. Energy Storage Capabilities

The energy stored in a capacitor is determined by the formula \(E = \frac{1}{2}CV^2\), where \(E\) is energy, \(C\) is capacitance, and \(V\) is voltage. Pulse capacitors are built to maximize this energy storage capability, enabling them to deliver significant power in short bursts.

B. Comparison with Standard Capacitors

1. Differences in Design and Functionality

While standard capacitors are often used for filtering and smoothing applications, pulse capacitors are specifically designed for high-energy applications. Their construction typically involves materials and designs that can withstand rapid changes in voltage and current.

2. Applications of Standard vs. Pulse Capacitors

Standard capacitors are commonly found in power supply circuits, audio equipment, and signal processing. In contrast, pulse capacitors are used in applications such as laser systems, power inverters, and electric vehicle powertrains, where rapid energy delivery is crucial.

III. Key Features of Pulse Capacitors

A. High Energy Density

1. Explanation of Energy Density

Energy density refers to the amount of energy stored per unit volume or mass. Pulse capacitors are designed to have high energy density, allowing them to store more energy in a smaller footprint.

2. Benefits in Compact Applications

This high energy density is particularly beneficial in applications where space is limited, such as in portable electronics or compact power systems, enabling designers to create smaller, more efficient devices.

B. Fast Charge and Discharge Rates

1. Importance of Speed in Applications

The ability to charge and discharge rapidly is one of the defining features of pulse capacitors. This speed is critical in applications that require immediate energy delivery, such as in pulsed laser systems or high-frequency power supplies.

2. Examples of High-Speed Applications

Examples include medical devices that require quick bursts of energy for imaging or therapeutic purposes, as well as automotive applications where rapid acceleration is necessary.

C. Voltage Ratings

1. Overview of Voltage Ratings in Pulse Capacitors

Pulse capacitors are available in a range of voltage ratings, allowing them to be used in various applications that require different levels of voltage tolerance.

2. Importance of Voltage Tolerance in Applications

High voltage ratings ensure that pulse capacitors can operate safely and effectively in demanding environments, such as in power electronics and industrial machinery.

D. Temperature Stability

1. Operating Temperature Range

Pulse capacitors are designed to operate effectively across a wide temperature range, ensuring reliability in various environmental conditions.

2. Impact of Temperature on Performance

Temperature stability is crucial, as extreme temperatures can affect the performance and lifespan of capacitors. Pulse capacitors are engineered to maintain their performance even in challenging conditions.

E. Low Equivalent Series Resistance (ESR)

1. Definition of ESR

Equivalent Series Resistance (ESR) is a measure of the resistance encountered by the current flowing through a capacitor. Low ESR is a desirable feature in pulse capacitors, as it minimizes energy loss during operation.

2. Benefits of Low ESR in Pulse Applications

Low ESR allows pulse capacitors to deliver energy more efficiently, making them ideal for high-frequency applications where energy loss can significantly impact performance.

F. Long Cycle Life

1. Definition of Cycle Life

Cycle life refers to the number of charge and discharge cycles a capacitor can undergo before its performance degrades. Pulse capacitors are designed for long cycle life, ensuring reliability in demanding applications.

2. Importance in Reliability and Longevity

A long cycle life is essential for applications where capacitors are subjected to frequent energy pulses, such as in electric vehicles and industrial machinery, where downtime can be costly.

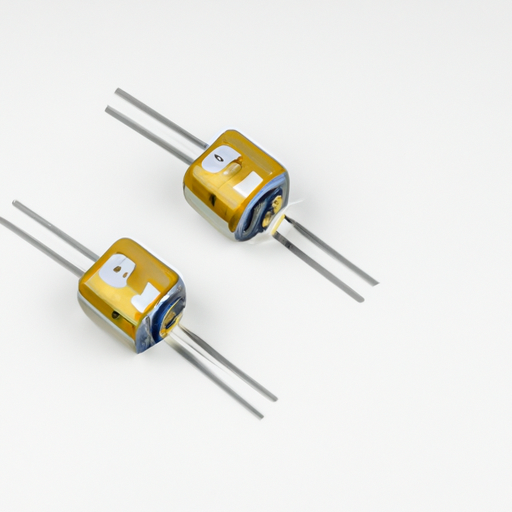

G. Robust Construction

1. Materials Used in Pulse Capacitors

Pulse capacitors are constructed from high-quality materials that can withstand the stresses of rapid charge and discharge cycles. Common materials include specialized dielectrics and conductive metals.

2. Resistance to Environmental Factors

The robust construction of pulse capacitors also provides resistance to environmental factors such as humidity, temperature fluctuations, and mechanical stress, ensuring reliable performance in various conditions.

IV. Types of Pulse Capacitors

A. Film Capacitors

Film capacitors are known for their excellent stability and low ESR, making them suitable for high-frequency applications. They are often used in power electronics and audio equipment.

B. Ceramic Capacitors

Ceramic capacitors are compact and offer high capacitance values. They are commonly used in telecommunications and consumer electronics due to their reliability and performance.

C. Electrolytic Capacitors

Electrolytic capacitors are known for their high capacitance and energy storage capabilities. They are often used in power supply circuits and energy storage applications.

D. Supercapacitors

Supercapacitors, or ultracapacitors, offer extremely high capacitance and are capable of rapid charge and discharge cycles. They are increasingly used in applications requiring quick bursts of energy, such as in electric vehicles and renewable energy systems.

V. Applications of Pulse Capacitors

A. Power Electronics

In power electronics, pulse capacitors play a crucial role in inverters and converters, enabling efficient energy conversion and management.

B. Automotive Industry

Pulse capacitors are essential in electric and hybrid vehicles, where they provide the necessary power for acceleration and regenerative braking systems.

C. Telecommunications

In telecommunications, pulse capacitors are vital for signal processing, ensuring that signals are transmitted efficiently and without distortion.

D. Medical Devices

Pulse capacitors are used in diagnostic and therapeutic equipment, where quick energy delivery is essential for imaging and treatment applications.

E. Industrial Equipment

In industrial settings, pulse capacitors are employed in motor drives and robotics, enhancing performance and efficiency in automated systems.

VI. Advantages of Using Pulse Capacitors

A. Enhanced Performance

Pulse capacitors provide enhanced performance in applications requiring rapid energy delivery, improving overall system efficiency.

B. Increased Efficiency

Their ability to minimize energy loss through low ESR and high energy density contributes to increased efficiency in various applications.

C. Cost-Effectiveness in Long-Term Use

While pulse capacitors may have a higher initial cost, their long cycle life and reliability can lead to cost savings over time.

D. Versatility Across Different Industries

Pulse capacitors are versatile components that can be adapted for use in a wide range of industries, from automotive to telecommunications.

VII. Challenges and Considerations

A. Cost Factors

The advanced materials and engineering required for pulse capacitors can lead to higher costs compared to standard capacitors, which may be a consideration for some applications.

B. Size and Weight Limitations

While pulse capacitors are designed to be compact, their size and weight can still be a limitation in certain applications, particularly in portable devices.

C. Selection Criteria for Specific Applications

Choosing the right pulse capacitor for a specific application requires careful consideration of factors such as voltage rating, capacitance, and environmental conditions.

D. Environmental Impact and Disposal

As with all electronic components, the environmental impact and proper disposal of pulse capacitors should be considered, particularly in industries focused on sustainability.

VIII. Conclusion

A. Summary of Key Features

Pulse capacitors are essential components in modern technology, offering high energy density, fast charge and discharge rates, and robust construction. Their unique features make them suitable for a wide range of applications.

B. Future Trends in Pulse Capacitor Technology

As technology continues to evolve, advancements in materials and design will likely lead to even more efficient and reliable pulse capacitors, further expanding their applications.

C. Final Thoughts on the Importance of Pulse Capacitors in Modern Technology

In conclusion, pulse capacitors play a critical role in enhancing the performance and efficiency of various systems across multiple industries. Their ability to deliver rapid bursts of energy makes them indispensable in today’s fast-paced technological landscape.

IX. References

A. Academic Journals

- Journal of Applied Physics

- IEEE Transactions on Power Electronics

B. Industry Reports

- Capacitor Market Analysis Report

- Trends in Energy Storage Technologies

C. Manufacturer Specifications

- Manufacturer datasheets for pulse capacitors

- Technical specifications from leading capacitor manufacturers

D. Relevant Online Resources

- Capacitor technology blogs

- Online forums discussing pulse capacitor applications and innovations

This comprehensive overview of pulse capacitors highlights their significance in modern technology, showcasing their features, applications, and the challenges they face. Understanding these aspects is crucial for engineers and designers looking to leverage the benefits of pulse capacitors in their projects.